Produce is placed in an insulated room equipped with refrigeration units. This method can be used with most commodities, but is slow compared with other options. A room used to store previously cooled produce requires a relatively small refrigeration unit.

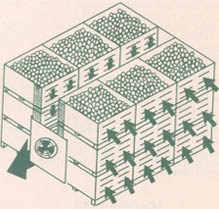

However, if the room is used to cool produce, a larger unit is needed. Containers are stacked so that cold air can move around them, and constructed so that it can move through them.

Fans are used in conjunction with a cooling room to pull cool air through packages of produce. Although the cooling rate depends on the air temperature and the rate of air flow, this method is usually 70-90 percent faster than room cooling.

Fans are used in conjunction with a cooling room to pull cool air through packages of produce. Although the cooling rate depends on the air temperature and the rate of air flow, this method is usually 70-90 percent faster than room cooling.

Fans can be equipped with a thermostat that automatically shuts them off as soon as the desired product temperature is reached. To avoid over-cooling and dehydration of produce, forced-air fans are only operated until the produce has been cooled to its optimum temperature. Forced-air Cooling has many applications, such as tree fruits or berries.

Icing is particularly effective on dense products and palletized packages that are difficult to cool with forced air. In top icing, crushed ice is added to the container over the top of the produce by hand or machine. In case of liquid icing, a slurry of water and ice is injected into packaged produce through vents or handholds.

Icing methods work well with high-respiration commodities such as sweet corn and broccoli. One Kg of ice will cool about three Kgs of produce from 30° C to 4° C.

Running cold water over produce is an efficient way to remove heat, and can serve as a means of cleaning at the same time. In addition, hydro-cooling reduces water loss and wilting. Use of disinfectant in the water is possible to reduce the spread of diseases.

Running cold water over produce is an efficient way to remove heat, and can serve as a means of cleaning at the same time. In addition, hydro-cooling reduces water loss and wilting. Use of disinfectant in the water is possible to reduce the spread of diseases.

Water removes heat about five times faster than air, but is less energy-efficient. Recirculated hydro-cooling water should be chlorinated to minimize disease problems. Hydro-cooling is not appropriate for commodities that cannot tolerate wetting.

If you are interested in one of these alternative cooling methods, please contact us directly and we will consult you about available options. Our cooling solutions are custom-made according to your requirements.

TEL: + 86 21 51089946

FAX: + 86 21 52272259

E-mail: enquiry@focusun.com

Available from 8.30 – 17.30 (UTC+08:00)